Photolithography

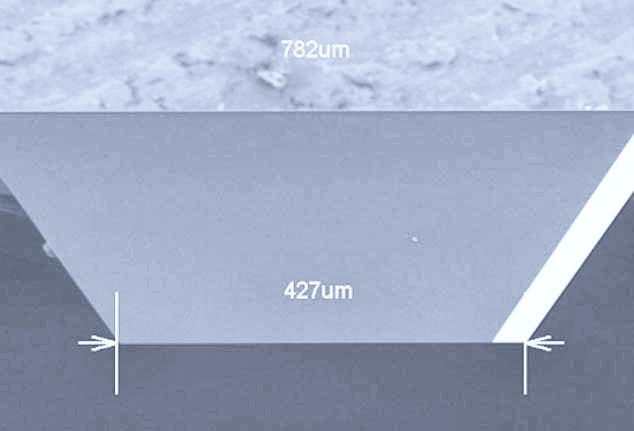

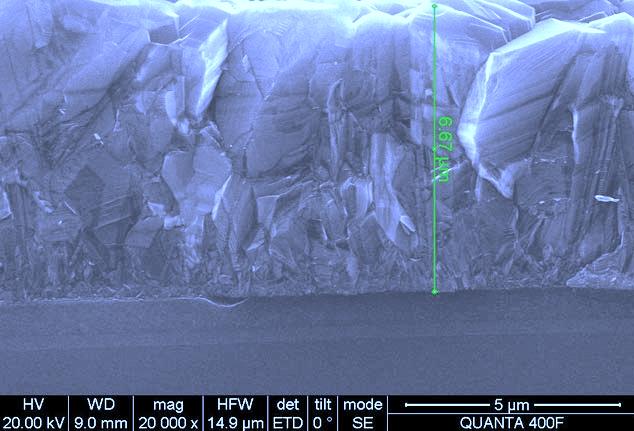

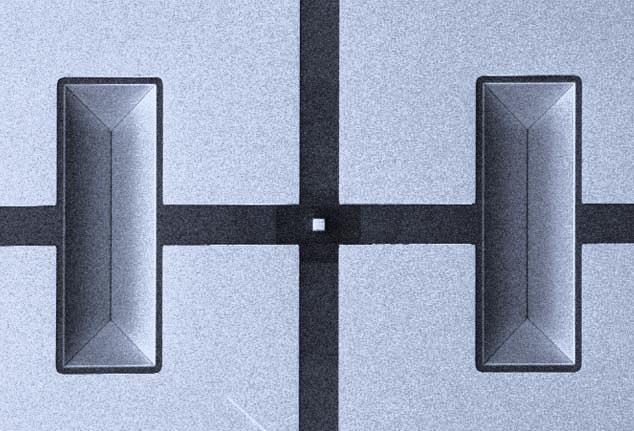

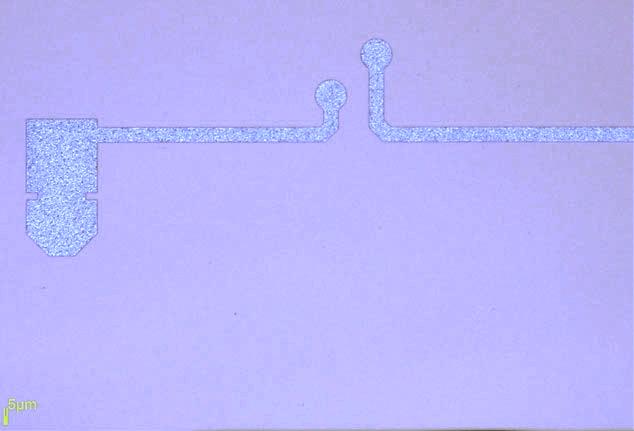

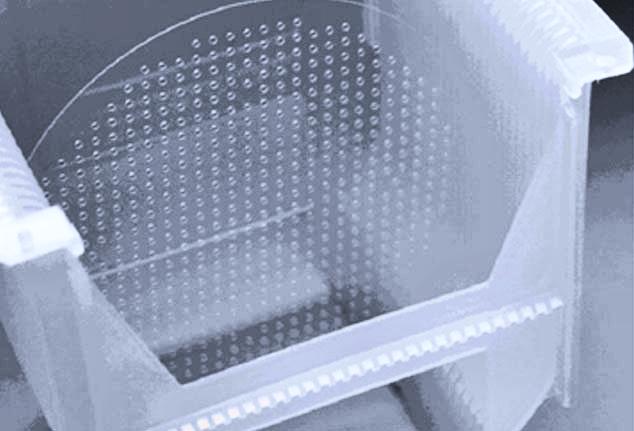

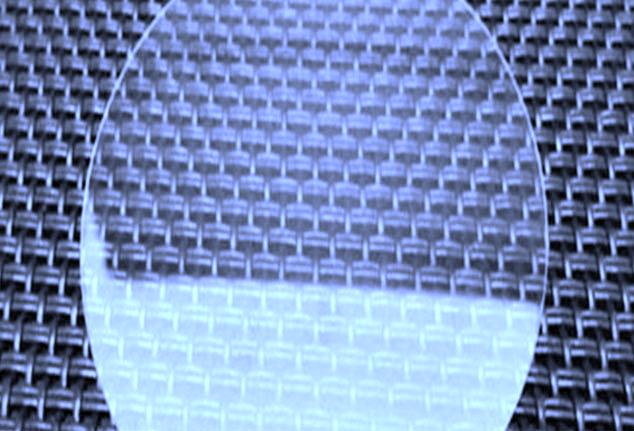

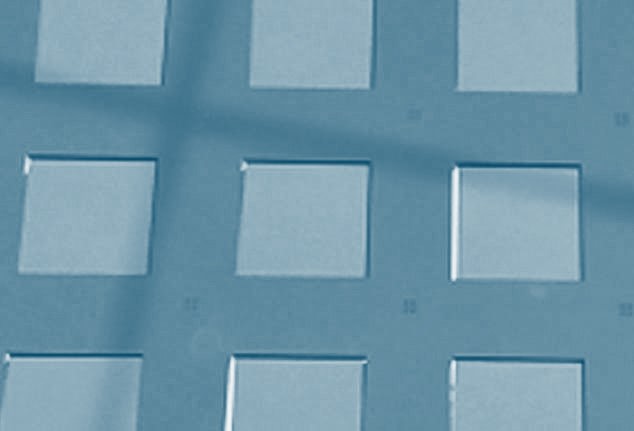

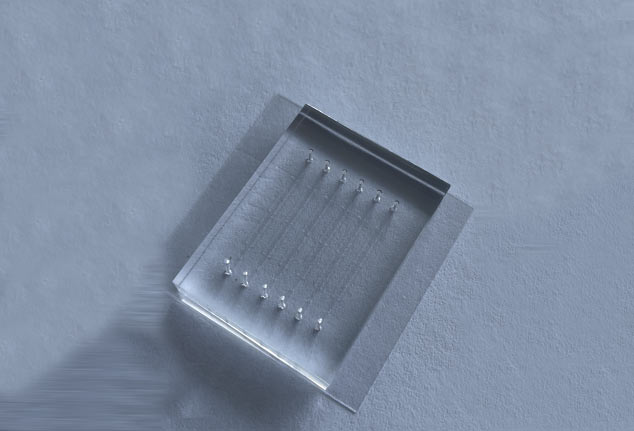

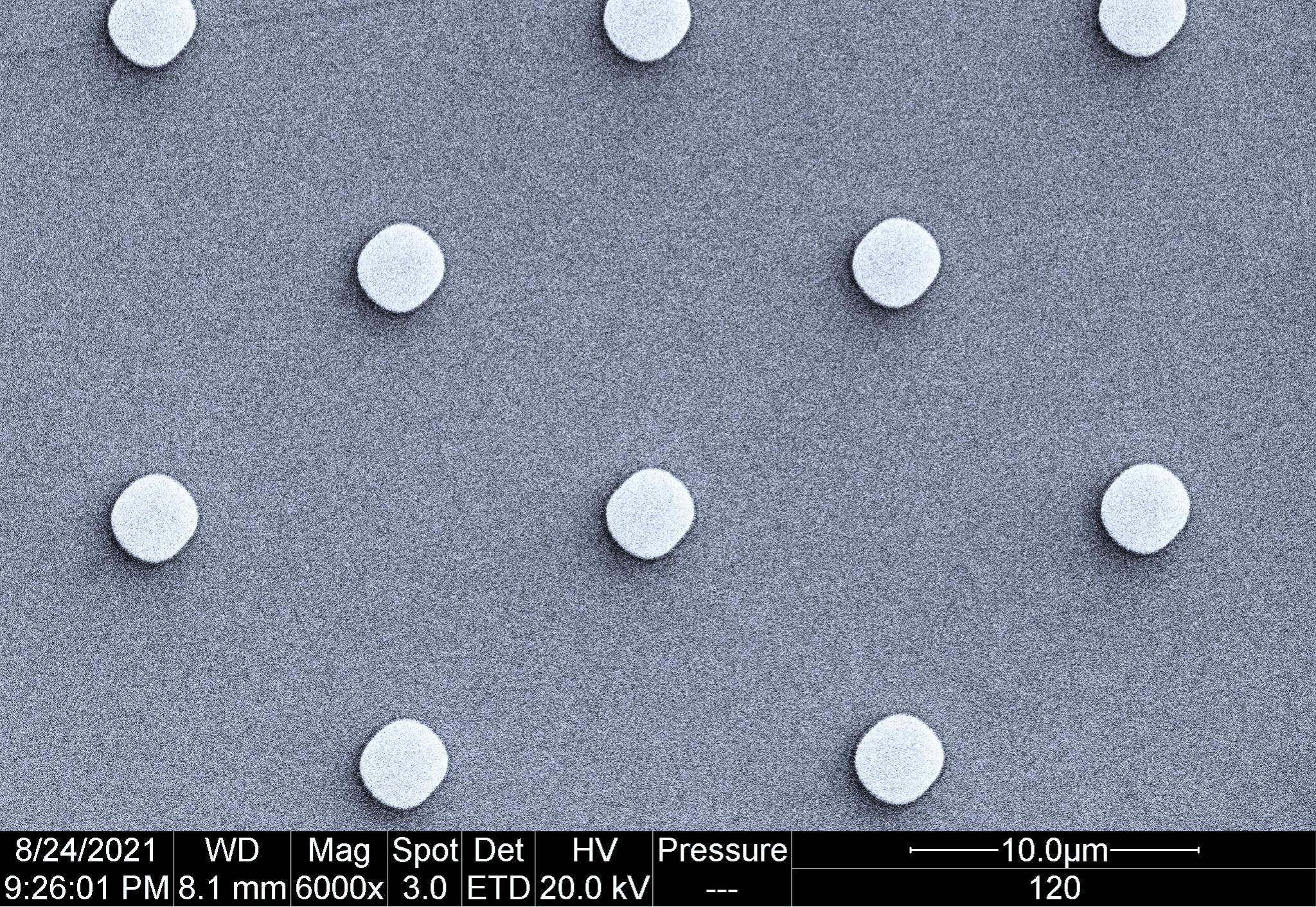

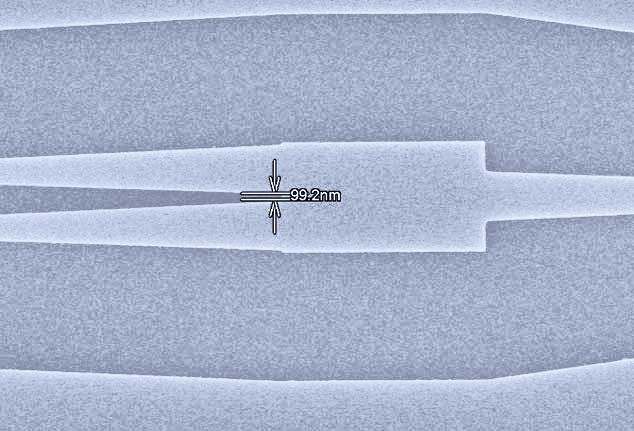

Photolithography is a cornerstone of semiconductor and MEMS fabrication, enabling precise patterning at the microscale and nanoscale. This advanced technique uses light to transfer intricate patterns onto wafer surfaces, creating openings in masking layers like silicon dioxide for localized impurity diffusion. Essential for defining device structures, photolithography allows for high-resolution patterning, layer alignment, and miniaturization, which are crucial for producing complex integrated circuits and MEMS devices. With state-of-the-art photolithography processes, we support innovations in electronics, sensors, and nanotechnology, providing the precision and control needed for next-generation device manufacturing. Applicable Substrates: Silicon wafers, glass, sapphire, flexible materials, and other substrates. Contact Lithography: Minimum feature size: 1 μm; overlay accuracy: ±0.5 μm. Stepper Projection Lithography: Projection ratio: 1:5; minimum feature size: 0.35 μm; overlay accuracy: ≤0.15 μm (X, Y); maximum exposure field: <22 x 22 mm. Electron Beam Lithography (EBL): Minimum feature size: 10 nm; overlay accuracy: 40 nm; maximum exposure diameter: <100 mm. Double-Sided Lithography: Minimum feature size: 1 μm; front-side overlay accuracy: ±1 μm; backside overlay accuracy: ±2 μm.