Mechanical exfoliation is an effective method for fabricating high-quality heterojunctions by transferring two distinct 2D materials, layer by layer, from bulk crystalline sources. This technique involves physically peeling thin layers of different bulk materials using adhesive tape (such as scotch tape) and then sequentially transferring them onto a chosen substrate to form a heterojunction.

In this process, we start by mechanically exfoliating a layer of the first 2D material, such as MoS₂, WS₂, or graphene, and transferring it onto the client’s selected substrate. After the first layer is successfully placed, a second 2D material is exfoliated and carefully aligned on top of the first layer, creating the desired heterojunction structure. This process is flexible and can be performed on a variety of substrates, including PET, PI, ITO, FTO, glass, metal substrates, and others.

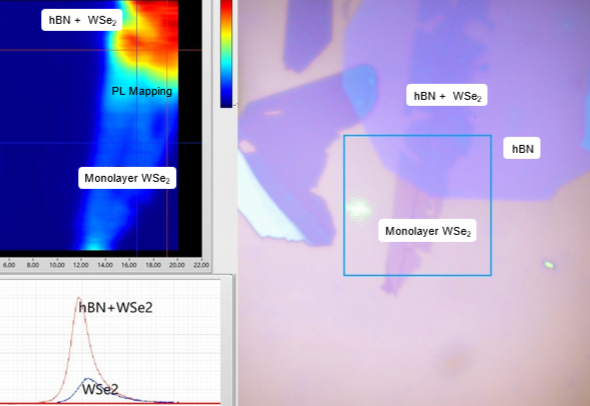

The heterojunctions created through mechanical exfoliation exhibit high crystallinity and strong interlayer interactions, making them ideal for applications in electronic, optoelectronic, and energy-harvesting devices. This method preserves the intrinsic properties of the individual materials while enabling the exploration of novel electronic and optical phenomena that arise from the heterostructure.

Our mechanical exfoliation service for heterojunction fabrication offers a reliable and versatile solution for researchers and innovators looking to create high-quality 2D material heterojunctions on their preferred substrates.

©2025 Nano store