Our MEMS dicing and drilling services provide precise material separation and micro-hole fabrication for a wide range of applications, from semiconductor and LED chip manufacturing to medical and consumer electronics. Using advanced dicing and drilling techniques, we ensure accuracy and reliability for various substrate types and device requirements.

Laser Dicing: Ideal for silicon substrates with thicknesses ranging from 100 to 700 μm; compatible with 2-inch, 4-inch, 6-inch, and 8-inch wafers.

Blade Dicing: Suitable for cutting materials such as silicon (Si), germanium (Ge), glass, quartz, ceramics, and printed circuit boards, using both soft and hard blades for optimized precision.

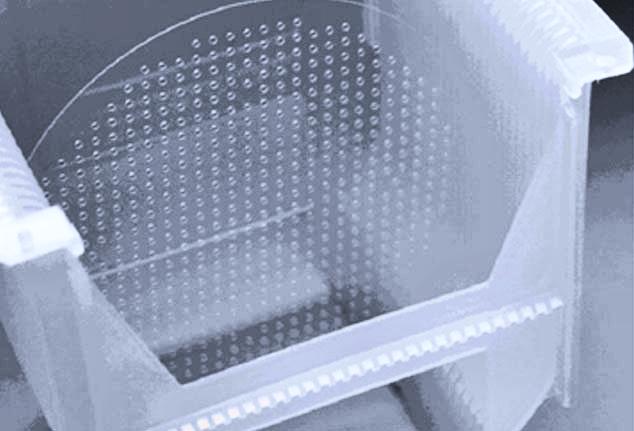

Micro-Drilling: Supports drilling micro-scale holes in various materials, essential for industries including LEDs, touchscreens, LCDs, consumer electronics, MEMS, lighting, and medical devices.

©2025 Nano store